Do you ever pick up a random item around your home or office and, just for the briefest of seconds, wonder how it gets made?

Well, thanks to the Discovery Science Channel, there is a series called “How It’s Made” and much like the title suggests, it is dedicated to sharing the production details about how certain items from our everyday lives get made.

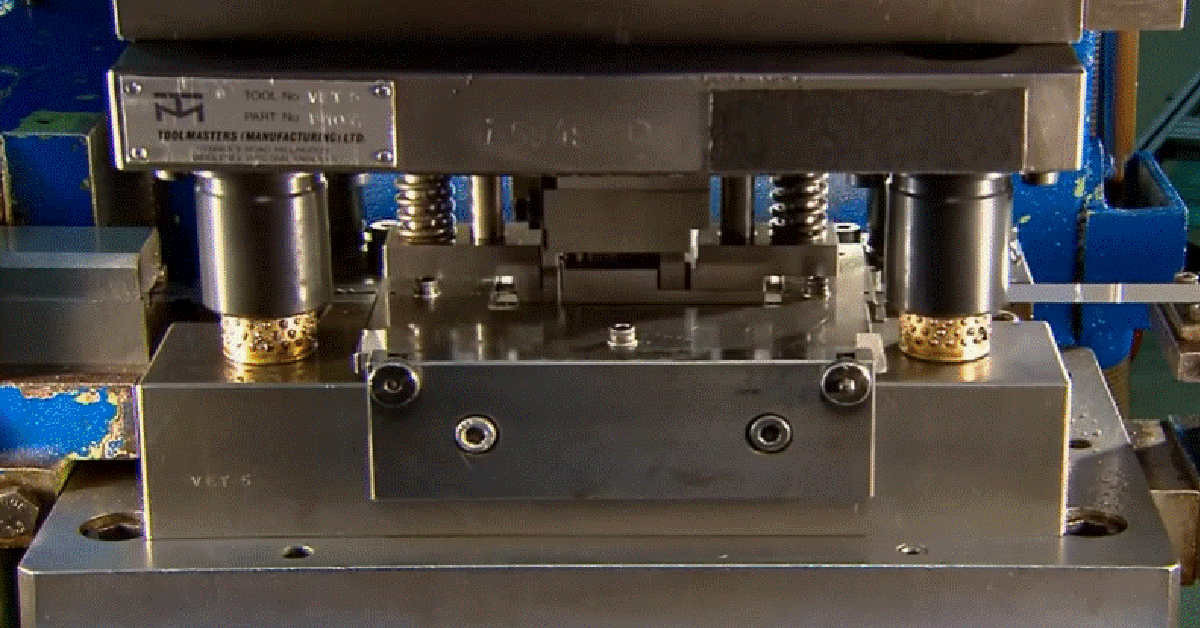

One of the episodes features the engineering and production behind the double-edged shaving razor blades.

We often take for granted the little toiletries such as razors. In our modern world, hair removal has never been easier if you want to shave it off, whereas back in the days of our ancient ancestors, sharpened pieces of flint would be the go-to standard for hair removal.

As they explained in the episode, “Cavemen sharpened pieces of flint and used them to shave their facial hair. Modern man can simply go purchase a pack of razor blades for his shaver. …They’re paper-thin yet sharp enough and strong enough to cut through the coarsest beard. Razor blades are made from a stainless steel strip that’s a mere four one-thousandths of an inch thick.”

The old method doesn’t sound easy, comfortable, or effective!

Each blade begins as a single strip of metal that is cut, heated, cooled, then heated again. Once it goes through this process, it gets branded and is sent off to the grinding and polishing machine that creates the double edges by separating the blades from each other. Once done, it is sent through a few other steps before each individual blade gets tested, coated, and then packaged up for distribution at a retailer.

Watch the video below:

What do you think? Let us know!